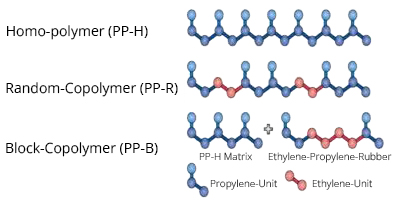

Polypropylene (PP) can be divided into three types, Homo-polymer polypropylene (PP-H), Block-Copolymer polypropylene (PP-B), and Random-Copolymer polypropylene (PP-R). Below are the advantages and disadvantages as well as some uses for these kinds of PP.

1. Introduction of three different polypropylenes

1.1. Homo-polymer polypropylene (PP-H)

Homo-Polymer Polypropylene is polymerized from a single propylene monomer. Its molecular chain does not contain ethylene monomer, and, therefore, is highly regular. Thus, the material has high crystallinity but poor impact performance. In order to decrease the brittleness of PP-H, some raw material suppliers blend and modify polyethylene and ethylene-propylene rubber to increase the material’s flexibility. However, this does not fundamentally solve the long-term heat resistance and stability of PP-H.

Advantages: Strong.

Disadvantages: poor impact resistance (brittle), poor resistance, poor dimensional stability, ages quickly, poor long-term heat resistance, and relatively unstable.

Uses: extrusion blow molding, flat yarn thread manufacture, injection molding, fiber mixing, blown film. It is used for packing belts, bottle blowing, brushes, ropes, woven bags, toys, folders, electrical appliances, household items, microwave lunch boxes, storage boxes, and paper film wrapping paper.

Distinguishing method: When the material is burned then the wire is flat and short when pulled.

1.2. Random-Copolymer polypropylene (PP-R)

Random-Copolymer polypropylene is manufactured by the copolymerization of propylene monomer and a small amount of ethylene (1-4%) monomer that is heated, pressured, and catalyzed. The ethylene monomer is randomly distributed along the chain of propylene. The random addition of ethylene reduces the polymer’s crystallinity and melting point. Meanwhile, it improves the material’s impact, long-term hydrostatic pressure, long-term heat and oxygen aging resistance. It makes it more suitable for pipe processing and molding. The molecular chain structure of PP-R and the ethylene monomer content directly affect the material’s long-term thermal stability and mechanical properties. The more random the distribution of ethylene monomer in the propylene molecular chain, the more significant the change in the polypropylene’s properties.

Advantages: excellent comprehensive performance, high strength, heat resistant, dimensional stability, excellent low-temperature toughness (good flexibility), highly transparent, and high gloss.

Disadvantages: poor high-temperature resistance and poor rigidity.

Uses: extrusion blow molding, injection molding and film manufacture. Tubing, shrink wrap, drip bottles, highly transparent containers, transparent household products, disposable syringes, and wrapping paper films.

Identification method: When ignited, it remains transparent. It forms a long round wire when stretched.

1.3. Block-Copolymer polypropylene (PP-B)

Block-Copolymer polypropylene has a relatively high ethylene content of 7 to 15%. However, the probability of two ethylene monomers and three monomers connecting in PP-B is very high. That means the ethylene monomer only exists in the block phase and does not reduce the PP-H regularity. Therefore, it cannot achieve its purpose of increasing the PP-H melting point, long-term hydrostatic pressure resistance, long-term heat-oxidative aging resistance, and pipe processing and molding capability.

Advantages: increased impact resistance and rigidity.

Disadvantages: low transparency and low gloss.

Uses: extrusion blowing and injection molding, fenders, thin-walled products, baby strollers, sports equipment, luggage, paint buckets, and battery boxes.

Identification method: When ignited, It does not turn black. It produces a long round wire when stretched.

2. Common features and differences of different polypropylenes

2.1.

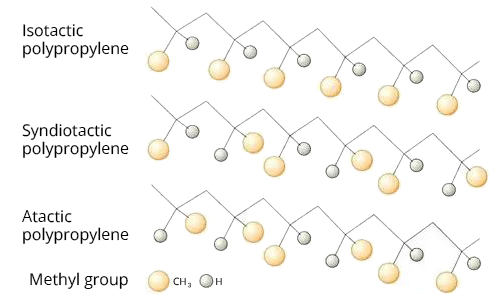

When propylene is polymerized it produces a thermoplastic resin called polypropylene. It becomes either Isotactic polypropylene, Atactic polypropylene, or Syndiotactic polypropylene, depending on the position of the methyl group.

It is called Isotactic polypropylene when the methyl groups are located on the same side of the main molecular chain. However, when the methyl groups are randomly arranged on either side of the molecular chain, It is called Atactic polypropylene. It is called Syndiotactic polypropylene when the methyl groups are alternately arranged on either side of the main molecular chain. In the typical industrial production of polypropylene resin, the Isotactic structure content is approximately 95%; the rest is Atactic or Syndiotactic polypropylene. Industrial products are primarily composed of isotactic substances. Polypropylene also includes propylene copolymers and a small amount of ethylene. It is typically solid, translucent, colorless, odorless, and non-toxic.

2.2.

APP Random Polypropylene

Please be aware that the random polypropylene we often talk about refers to 1.2. Propylene-ethylene (random) copolymer. The English abbreviation is PP-R. However, the arrangement of methyl groups distinguishes the random polypropylene we refer to here. The English abbreviation is APP. Due to its stable structure and high crystallization, the melting point of homopolymerized PP can be as high as 167°C. It is the lightest general-pupose plastic and has a relatively low density.

Advantages:

Its outstanding advantages are heat and corrosion resistance, and it can be sterilized by steam. Other advantages include resistance to moisture absorption, acid and alkali corrosion, dissolution, and excellent dielectric and electrical insulation.

Disadvantages:

The disadvantage is poor impact resistance at low temperatures and poor oxidation resistance at high temperatures. However, both can be overcome by modification. The shrinkage rate of PP is approximately 1.5-2.5%. This is relatively high and occurs due to crystallization.

2.3.

The typical MFR of PP ranges from 1- 40. MFR of approximately 100 is relatively rare. PP materials with low MFR are more impact resistant but have lower strength when elongated. When materials have a similar MFR, the copolymer type is stronger than the homopolymer type. When a nucleating agent is added, PP-R becomes more transparent than PP-H. PP-H has more resistance to high temperatures than PP-B.

转自聚丙烯人