Laboratories around the world generate a significant amount of plastic waste every day. According to a 2015 study published in Nature, scientific research labs produce over 5.5 million tons of plastic waste annually, with much of it ending up in landfills or incinerators. From pipette tips and PCR tubes to centrifuge vials and storage boxes, disposable plastic consumables are deeply embedded in modern lab workflows—and often used only once.

While these materials are essential for sterility and precision, improper disposal can lead to serious environmental consequences, potential safety risks, and non-compliance with regulatory standards. As sustainability becomes a growing priority in science and industry, laboratories are increasingly being urged to rethink how they manage plastic waste.

At GenFollower, we are committed to environmental protection and reducing plastic pollution. If you’re looking to better understand how to classify laboratory plastic waste and explore safer, more sustainable disposal methods, here are some helpful recommendations.

How to sort laboratory plastic waste

Effective waste classification is the critical first step toward sustainable lab operations. Proper segregation reduces landfill burden by 60% and cuts hazardous incidents by 90% (WHO Lab Safety Report, 2024). Misclassified plastics not only contaminate recyclable streams but escalate disposal costs by 3-7x.

The following classification scheme is designed to classify laboratory plastics based on biological/chemical risk exposure and material integrity as the primary determinants, consistent with the U.S. Environmental Protection Agency (EPA) Resource Conservation and Recovery Act (RCRA) guidelines.

1. Recyclable Plastics♻️

These items retain structural integrity and lack any exposure to biohazardous agents, organic solvents, or radioactive materials. Crucially, they must pass the “three-rinse test” – visible residue or odor after water rinsing disqualifies them.

Common Lab Consumables:

PET (Polyethylene Terephthalate): Uncontaminated centrifuge tubes, cryoboxes (labels/caps removed).

HDPE (High-Density Polyethylene): Reagent bottle caps, solvent jugs (degreased with ethanol).

PP (Polypropylene): Pipette tip racks, PCR tube holders (hinges disassembled).

Consequences of Mishandling:

Economic & Environmental Loss: Incinerating 1 kg of clean PET tubes wastes $0.80 of recyclable material and emits 1.8 kg CO₂ – equivalent to driving 4 miles in a standard car.

Recycling Stream Contamination: A single HDPE cap with residual acetone can degrade a 100 kg PP batch, forcing landfill disposal.

2. Non-Recyclable Plastics⚠️

Plastics are designated non-recyclable if they exhibit chemical compromise (e.g., exposure to xylene, DMSO, radioisotopes) or irreparable physical damage (cracks, warping). Even decontaminated items retain molecular residues that disrupt recycling chemistry.

Typical Examples:

Centrifuge tubes used with organic solvents (e.g., acetonitrile in HPLC).

Shattered Petri dishes or culture plates.

PS (polystyrene) electrophoresis trays stained with Coomassie blue.

If you mishandle it, there will be the following risks:

Toxic Emissions: Burning PVC-containing items (e.g., IV bags) without >850°C incineration releases dioxins – carcinogens that bioaccumulate in aquatic ecosystems.

Resource Inefficiency: Landfilling chemically contaminated PP wastes 11 kWh/ton of potential energy – enough to power a lab autoclave for 15 cycles.

3. Hazardous Contaminated Plastics☣️

This category includes plastics contacting BSL-2+ pathogens (e.g., SARS-CoV-2 transport media), human-derived materials (blood, tissues), or cytotoxic compounds (e.g., chemotherapeutic agents). The presence of these hazards mandates pre-treatment before any disposal.

Critical Lab Items:

Virus-contaminated pipette tips and microcentrifuge tubes.

Blood-stained cryovials or IV bags.

Electrophoresis equipment with heavy metal stains (e.g., cadmium, lead).

If these items are not handled correctly, the consequences can be disastrous:

Biohazard Outbreaks: Discarding untreated BSL-2 waste in standard bins risks nosocomial infections – a 2024 WHO study linked 12% of lab-acquired infections to improper waste handling.

Ecosystem Toxicity: Autoclaving metal-contaminated plastics releases bioavailable heavy metals into landfills, poisoning soil microbiota and entering food chains.

How to process laboratory plastic waste step by step

Effective laboratory plastic waste management requires a meticulously orchestrated chain of custody. This section delineates the sequential workflow from waste generation to final treatment, integrating safety protocols, regulatory compliance, and sustainability imperatives. Each phase builds upon the previous to ensure contaminants are contained, resources recovered, and environmental impacts minimized.

Phase 1: Waste Generation & Source Segregation

The process begins at the laboratory bench, where immediate segregation dictates downstream handling efficacy. Plastic waste must be separated into three streams at the point of generation:

Recyclable plastics (e.g., unused centrifuge tubes, untainted reagent bottles) are rinsed using the ”three-rinse test” to confirm no residual contaminants.

Non-recyclable plastics (e.g., solvent-contaminated tubes, shattered culture plates) are deposited into yellow biohazard bags labeled for incineration.

Hazardous plastics (e.g., pathogen-exposed pipette tips, blood-stained vials) undergo pre-sterilization via autoclaving (121°C, 30 psi, 45 minutes) before containment in puncture-proof sharps containers or leak-proof bins.

In addition, all containers must display chemical compatibility labels (e.g., HDPE for acids, PP for solvents) to prevent reactions, and be filled only to 90% capacity to accommodate thermal expansion.

Phase 2: Collection & Intermediate Storage

Segregated waste moves to designated storage zones, where temporal and spatial controls mitigate cross-contamination risks:

Recyclables are stored in blue, vented bins to prevent microbial growth, with resins (#1 PET, #2 HDPE, #5 PP) separated to streamline recycling.

Non-recyclables destined for incineration are held in temperature-controlled rooms (<25°C) to volatile organic compound (VOC) emissions.

Hazardous waste containers are placed in secondary containment trays (110% volume capacity) and stored in negative-pressure cabinets with HEPA filtration to contain aerosols.

Storage areas require daily integrity inspections for leaks, corrosion, or label degradation. Logs must document waste accumulation start dates, with maximum storage durations not exceeding 90 days to comply with RCRA guidelines.

Phase 3: Pre-Treatment & Conditioning

This phase transforms waste chemistry to enable safe transport and recovery:

For recyclable plastics (e.g., uncontaminated PET tubes, HDPE caps), conditioning begins with ethanol degreasing to remove surface residues, followed by UV irradiation to eliminate trace organic contaminants. Validation requires ATP swab tests confirming readings below 5 RLU (Relative Light Units), ensuring no biological activity remains.

Non-recyclable plastics exposed to solvents or radioisotopes undergo alkaline hydrolysis: immersion in 10% NaOH for 24 hours to break down organic residues like acetonitrile or xylene. This is paired with solidification using bentonite clay to immobilize heavy metals and prevent leaching during transport. Post-treatment pH testing must confirm neutral levels (6.5–7.5) to meet thermal recovery facility standards.

Hazardous plastics contaminated with pathogens or cytotoxic agents require tiered decontamination. Biological hazards (e.g., BSL-2+ virus samples) are inactivated via autoclaving at 121°C for 45 minutes, validated by Geobacillus stearothermophilus spore tests. Chemical hazards (e.g., cisplatin-contaminated syringes) are neutralized with 10% bleach immersion for 1 hour, followed by chelating agents like EDTA to sequester heavy metals. Crucially, solvent recovery units can distill 60% of acetonitrile from HPLC waste for reuse, drastically reducing virgin solvent consumption.

Phase 4: Transportation & Tracking

Waste leaves the laboratory via dedicated, UN-certified transport systems:

Recyclables are shipped in compaction-resistant containers to material recovery facilities (MRFs), tracked via blockchain-enabled manifests to prevent diversion to landfills.

Hazardous/non-recyclable waste is moved in refrigerated vehicles (4°C) to preserve sterility and minimize reactivity, with GPS-enabled sensors monitoring temperature/shock.

Regulatory documentation (e.g., EPA Form 8700-22) must accompany shipments, specifying waste codes (D001-D043), emergency contacts, and treatment destinations.

Phase 5: Final Treatment & Resource Recovery

The culmination of the waste management chain converts processed plastics into renewable feedstocks and energy, aligning with circular economy principles.

Recyclable plastics undergo extrusion-pelletization, where shredded material is melted and reformed into FDA-grade pellets. These pellets serve as raw material for new lab consumables (e.g., centrifuge tubes, tip racks), while microplastic capture filters (>99% efficiency) prevent environmental leakage during processing.

Non-recyclable plastics are directed to plasma gasification at >1,200°C, a thermal process that decomposes complex polymers into syngas (2.8 MWh/ton). This syngas fuels onsite turbines to generate electricity, powering facility operations. Advanced plants integrate dioxin scrubbers to capture halogenated compounds (e.g., from PVC IV bags) and slag vitrification to convert ash into inert construction aggregates, achieving zero landfill discharge.

Hazardous waste follows a dual-stage protocol: autoclave sterilization ensures biological safety, followed by oxygen-free pyrolysis that cracks organic molecules into carbon black. This carbon black is repurposed as industrial filler for rubber or asphalt, while heavy metal sequestration systems (e.g., EDTA-enhanced precipitation) isolate toxic elements like cadmium for secure encapsulation. Emerging solvolysis techniques now depolymerize polypropylene/polyester blends into monomers, enabling closed-loop remanufacturing of lab-grade plastics with 40% lower carbon footprint than virgin production.

Phase 6: Residual Management & Auditing

Post-treatment residues undergo final stabilization:

Incinerator ash is cement-encapsulated for construction filler use.

Biohazard treatment sludge undergoes microbial bio-augmentation to degrade organic residues.

Labs must conduct quarterly mass-balance audits, comparing waste generated versus resources recovered. Performance metrics (e.g., 95% landfill diversion, 40% carbon reduction vs. baseline) should align with ISO 14001 certification requirements.

Conclusion

The journey from bench to responsible disposal begins with rigorous classification—distinguishing recyclable, non-recyclable, and hazardous plastics by their contamination levels and material integrity—and extends through systematic processing workflows that transform waste into resources or safely neutralize threats. By adopting this dual framework of categorization and stepwise treatment, labs not only comply with global standards but actively mitigate ecological harm. Every correctly sorted centrifuge tube or decontaminated pipette tip contributes to reducing the 5.5 million metric tons of plastic waste labs generate annually—a staggering figure where currently <5% is recycled.

GenFollower’s E-Series Pipette Tips exemplify this ethos, engineered to reduce plastic consumption by ≥20% without compromising precision or durability. Their uniform-thin walls—validated for universal compatibility across major pipette brands—maintain ISO-certified accuracy while directly shrinking waste volumes.

GenFollower welcomes your inquiries about our consumables. Join us in advancing waste minimization practices and contributing to environmental protection and sustainable development.

Recent Posts

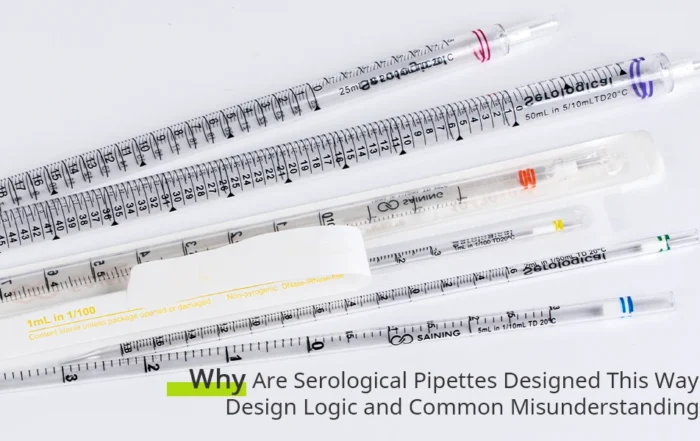

Why Are Serological Pipettes Designed This Way? Design Logic and Common Misunderstandings

Serological pipettes are part of everyday life in many laboratories. Whether transferring culture media, handling large liquid volumes, or supporting routine cell culture work, they are often picked up almost without thinking. Their shape, [...]

Plate Heat Sealer FAQs: What Often Goes Wrong and How Labs Fix It

Plate heat sealers are widely used in laboratories to protect samples from evaporation, leakage, and contamination. However, in daily use, many labs encounter recurring issues—inconsistent seals, unclear parameter settings, compatibility questions, or unexpected sealing [...]

ELISA Plate FAQs: 12 Common Problems That Affect ELISA Results

In a previous article, Step-by-Step ELISA Protocol: A Comprehensive Guide Step-by-Step ELISA Protocol: A Comprehensive Guide, we outlined the standard workflow of an ELISA assay, from plate coating and blocking to detection and data interpretation. [...]